Our highly specialized containment cells are a unique approach to providing a safer means of operating small, bench scale, high-pressure reactors which might be dangerous. In this approach, we contain hazardous high-pressure reactions to an ASME-code steel plate chamber. This offers R&D practitioners the opportunity to safely conduct high-pressure research in close or confined quarters.

Let’s discuss your Containment Cell needs!

Specifications

- Chamber Inner Diameter

- Chamber Interior

- Design Energy Level

- Total Weight

- Upper Chamber Weight

- Process Connections

- Service Sleeves

- Certifications

- Pressures

- Additional Features

29 Inches

Height 60 Inches

3/4 lbs. TNT

4000 lbs.

1800 lbs.

12 ea. 1/8″ tubing

6 each 3/4″ NPT

9 each 1/2″ NPT

ASME Code

800 psig (1200 psi test)

- Safe

- Portable

- Explosion and Missile Tested

- Quick and Easy Opening

- Hermetically Sealed

- Control of Internal Atmosphere

- Safety Interlock on Closure

- One Person Operability

- View Ports(s)

- Process and Service Feed throughs

Steel Barricade – High Pressure Cell Specifications

- Overview

- Outer Diameter

- Containment Options

- Barricade Energy

- Viewing Port

- Features

- Door Features

- Process Connections

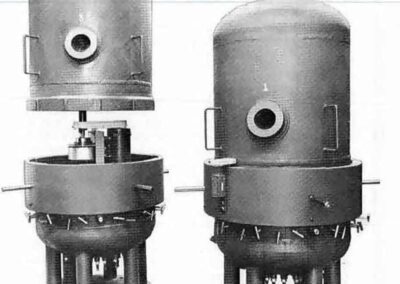

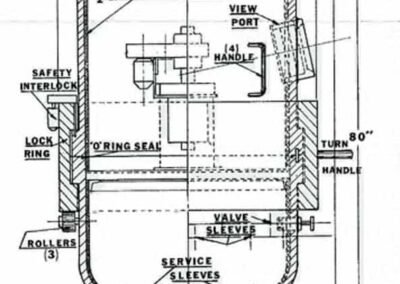

The basic chamber is fabricated of ASME Code steel plate and consists of upper and lower sections. The upper section contains only the view port(s) and a lift hook for removal. The window is specially designed and has been used for a number of years without any problems. It consists of two (2) pieces of heavy, laminated plastic separated by an air gap and sealed with “O” rings in a heavy steel frame welded to the shell. A piece of 1/4″ thick laminated safety glass is placed between the inner plastic window and the interior of the chamber to prevent chemical or solvent damage due to spills, vapors, etc. which might ordinarily attack or damage the plastic window. Extensive tests have been made by Fluitron with these windows to study the effects of pressure, blast waves and missiles of various sizes, mass and velocities.

The lower chamber section contains the valve sleeves which are located directly below the main lock ring. The valve handle extensions which go through these sleeves are sealed by “O” rings, and have safety shoulders to prevent blowout in case of equipment failure. The inside of the sleeves are machined to receive standard high pressure valves of various types and sizes by means of standoff brackets. The service sleeves are located in the dished head of the lower chamber section. (See table for sizes and types) The gas and liquid process sleeves are of 18-8 S.S. and the recommended tubing size is 1/8″ OD, although other sizes can be furnished. However, the 1/8″ OD tubing provides flexibility for installation and piping. Various commercial types of tubing connections are available. All penetrations are hermetically sealed and will stand a 1500 psi hydro test.

A Unistrut rack to provide flexibility is provided in the lower chamber section for support of the reactor.

The inside of the chamber is covered with a special multi layer, high temperature, highly chemical corrosion resistant resin and fiberglass construction, producing a final thickness up to 5/8″ maximum. A white gel-coat is then applied to the fiberglass to provide a smooth, white, reflective surface for good viewing of the interior and easy cleaning.

The basic closure of the chamber is of the breech lock type, i.e. the top chamber section has a heavy flanged lip which is cut out in six (6) places, permitting the main lock ring which has six (6) corresponding cutouts on the top side to pass through and mate with the bottom flange. Sealing is achieved by means of an “O” ring between the upper and lower chamber sections. A 30° rotation of the lock ring will then line up the lugs of the lock ring with the lugs of the top chamber. When the proper location of these lugs is reached an interlock pin is inserted, activating a micro switch, permitting the system to be operated.

The lower chamber section is welded to steel legs which in turn are welded to a heavy steel base plate that is drilled for bolting to twelve (12) studs cast into the concrete base (by customer).

However, Fluitron will provide a template for locating these studs as well as the recommended concrete support base. As an option Fluitron will supply a support plate with the required studs and nuts as an assembly that can simply be cast in the concrete floor. For additional information call or write for our technical paper “The Safe Containment of Total Chemical Hazards”.

For multiple units, removal and handling of the upper chamber section is usually accomplished by an overhead one ton electric hoist supported on overhead rails. However, Fluitron can provide a single gantry crane integrated with the base support plate which will allow a single operator to raise the upper section and swing it out of the way to provide working access to the equipment located within the chamber.

The size of the reactor which can be used in the containment cells depends on the energy level, design pressure and physical size. Agitated reactors in the range of 1 to 2 liters designed for 5000 psig can generally be accommodated.

8′ to 12′

Complete Containment

Vented

Levels Up to 15 lbs. of TNT

6 Inch

Complete Containment

Sound Deadening Liner

Valve and Service Sleeves

Vent Stack w/ Missile Catcher and Baffles

Blast Door w/ Ball Bearing Hinges and Safety Interlocks

Rectangular Access Door

Round Access Door

12 ea. 1/8″ tubing

Containment Cell Standard Connections

Valve Sleeves

12

Drain

1/2″ NPT

Vent

Pi1/4″ NPT