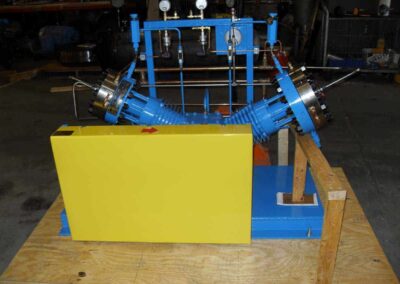

Large & small hydrogen compressors for any application

Thanks to their leak- & contaminant- free design, our hermetically sealed compressors stand out as the best choice for hydrogen fueling stations and hydrogen recovery systems. Manufactured in house, we design our hydrogen compressors using static metal seals to be safe & reliable up to 7,000 and 10,000 psig working pressures; they are leak free, contamination free, and corrosion resistant. For other gasses (see a list below), we can reach compression of more than 30,000psig working pressure.

During manufacture, we carefully test and inspect every component of the compressor to ensure it meets or exceeds performance and safety standards. For custom designs, we also ensure we meet our partner’s specifications. We can customize large or small hydrogen compressors for any application.

We pride ourselves on our dedication to our customers and provide maintenance service and troubleshooting for all our compressors.

Let’s get started on your project today!

Our compressors feature:

- Leak Free Design

- Contamination Free Compression

- Corrosion Resistance

- High Compression Ratios

- High Reliability

- Safety

- Automatic Leak Detection

We scrutinize every part manufactured and ensure our compressors meet or exceed performance and safety standards as well as fulfill our customer’s specifications. Our staff has over 35 years of experience in compression and high pressure applications. We provide maintenance and troubleshooting for all our compressors. We even customize and improve existing systems. Here at Fluitron, we pride ourselves on providing our customers with the highest quality system and support for their application. Our highly trained and experienced engineers are always available to ensure specifications are met and customers are satisfied.

Why specify our diaphragm compressor?

Leak Free

Contamination Free

High Compression Ratio

Automatic Leak Detection

Would you like to know more about how our automatic leak detection system works, or how we can custom design a diaphragm compressor to meet your needs?

Gas best suited for our compressors

Fluitron Diaphragm Compressors are ideal for a variety of gases, including:

- Toxic gases such as Carbon Monoxide

- Explosive gases such as Hydrogen, Ethylene, and Methane

- Reactive gases such as Oxygen and Fluorine

- Expensive gases such as Neon, Krypton, and Xenon

- Radioactive gases such as Tritium

- High Purity gases such as Nitrogen, Helium, Argon, etc.

Specifications

Skidded Package Options

- Aftercoolers

- Automatic on/off systems

- Control panels

- Flow control systems

- Motor starters

- Pressure and temperature gauges

- Pressure and temperature switches

- Pressure and temperature transmitters

Skidded Package Options

- Pressure control systems

- Pulsation Dampeners

- Receiver tanks

- Separators

- Suction Filter

Certifications

- ASME

- Pressure control systems

- Pulsation Dampeners

- Receiver tanks

- Separators

- Suction Filter

Certifications

- ASME