We are capable of fabricating both motor and hand high pressure syringe pumps

Series SP Motor Driven Syringe Pumps

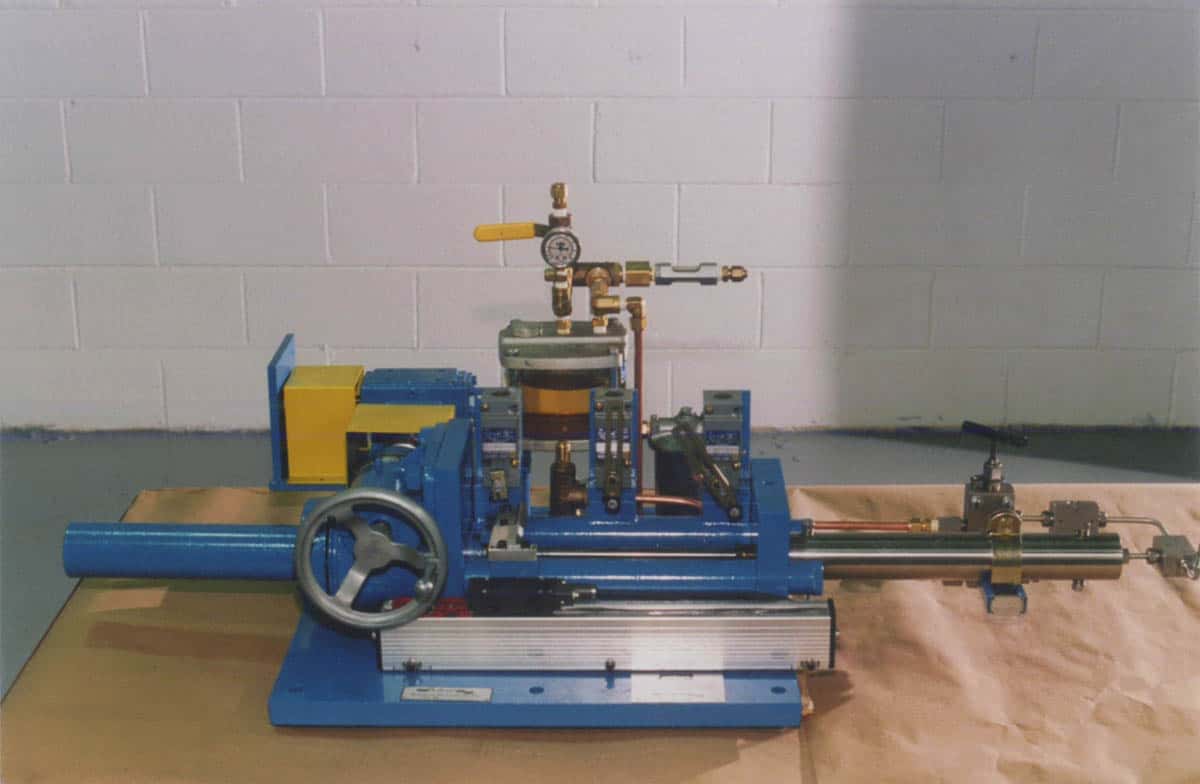

The Fluitron SP Series high-pressure syringe pumps are motor-driven, positive displacement pumps designed for the precise injection of catalysts and other fluids into high-pressure systems.

Using a slow-moving plunger moving through a larger “barrel” allows for the ability to control the flow rate using the motor speed. As a result, our syringe pumps provide a continuous, pulseless flow.

Another advantage of the SP Series syringe pump is that there are no check valves to malfunction, “miss a beat”, or respond differently to various flow conditions or fluid properties.

The SP series syringe pumps are available in various flow ranges, volumes, and pressures. For applications requiring continuous, pulseless flow over long periods of time, we can configure two pumps in a duplex arrangement.

Let’s discuss your High Pressure Pump needs!

(Series MP Hand Pumps

Our MP hand pumps cover a pressure range of 15,000 to 150,000 psi in five (5) models. They are easy to operate and maintain and are suitable for use with many fluids.

The linkage in the MP pumps is simple, and has a high mechanical advantage, permitting the development of high pressure with reasonable effort. The basic design results in a compact unit of low weight resulting in a portable high-pressure pump.

Our Pump materials are safe to use with distilled water; alcohol; synthetic oil; etc. The plungers in the 100,000 and 150,000 psi pumps are Tungsten Carbide, hand finished for wear resistance and low leakage. Plungers on other pumps are available in 17-4 SS, 316 SS, etc.

The check valves are springless, ball type, operating in cages providing the necessary guiding and lift required for proper operation. Vertical valves ensure complete air expulsion and quick priming.

Contact us to get your quote today!

Series SP Syringe Pump Specifications

Pressures

300 to 100,000 psi

Volume

7 cc to 1 L

Flow Measurement

1 cc/hr to 10,000 cc/hr

Continuous Operation

Standard single barrel syringe pumps are designed for batch type operations.

Depending on your application, Fluitron’s syringe pumps can be configured for near pulseless flow and continuous operation. The continuous pump features a double barrel design that utilizes two pumps running off a single motor.

The pumps would be set up 180 degrees out of phase so when one pump is discharging, the other pump is filling.

This option would only have a short time without any flow when the pump stops and reverses.

For pulseless flow, we design a complete pumping system with a single PLC control system. This system will at all times have one barrel operating and one barrel recharging and then building pressure. When the first barrel is near the end of it’s stroke it slows down and the second barrel speeds up. This would allow for a relatively pulseless transition between the two barrels.

Options

Control Systems

Microprocessor or PLC controls available for Flow and/or Pressure control

Special Materials

Breech-Lock

Quick-opening Pin

Threaded Closures

Jackets

Electric heat or vapor type jacket for the barrel for heating or cooling

Other Options

Piping – includes valves, fittings, tubing as required

Pressure Gauge

Safety Shield