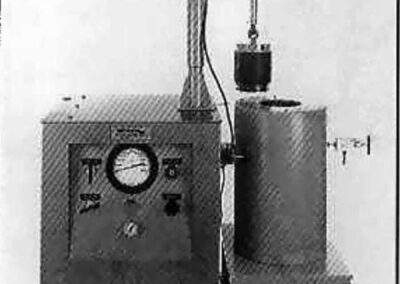

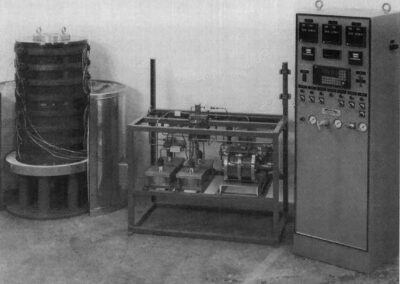

We fabricate both warm- and cold- isostatic pressing equipment in a variety of sizes and pressure ratings. Our isostatic pressing equipment features a compaction chamber, pressurizing pump, fluid reservoir, piping, and a convenient steel console.

Our isostatic vessels are perfect for the requirements of powder metallurgy or other applications requiring customizable levels of control and precision. Our experience ranges from manual control to fully automated process systems operating in production environments.

Features of our isostatic presses include:

- Manual, Microprocessor, PLC or PC Control (Labview or other software available)

- In-house Operating Software Programming

- Complete System Integration

- Computer Interface

- In-house PLC Programming

- Data Acquisition

- Turnkey Operation

Let’s discuss your Isostatic Pressing needs!

SPECIFICATIONS

Pressures

Up to 60,000 psi

Closures

Breech-Lock

Quick-opening Pin

Threaded Closures

Standard Chamber Diameter

From 1″ I.D to 10″ I.D.

Larger chambers available to 16″ I.D.

Length

From 6″ to 24″