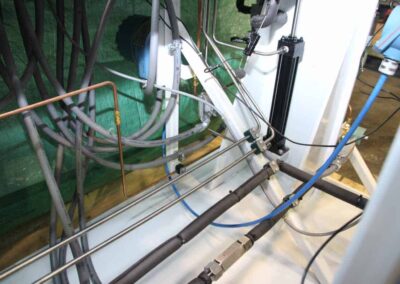

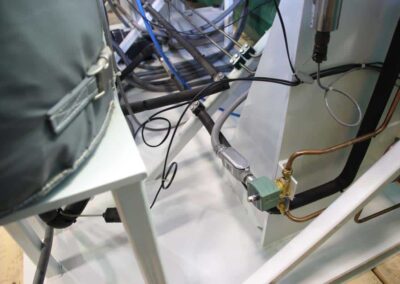

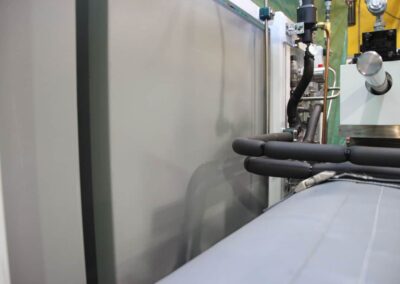

With a wide variety of experience in designing and manufacturing supercritical CO2 extraction equipment, we are certain we can assist you with your supercritical CO2 extraction project. We are capable of manufacturing custom open and closed loop CO2 extractors for a new custom design or of supplying components for others’ extraction systems.

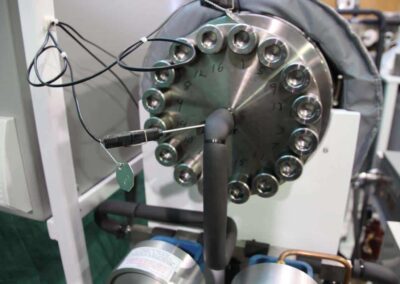

Our custom extractors can handle both liquid and gaseous sources, various temperature ranges, and up to 10,000 psi. We optimize our rugged designs for minimal complication and maximum reliability. All elements are customizable including automation and control levels, lock types, baskets, and integration with other custom metal diaphragm compressors, extractors, and separators.

Let’s discuss your Extraction Equipment needs!

Specifications

Pressure Rating @100° C

6000 psi

up to 30,000 psi

Materials of Construction

316 Stainless Steel

Solvent

Carbon Dioxide

Other solvents available

Options

CO2 Flow Control and Totalization

Extraction Chamber

Pressure Control

Pressurizing Pump/Compressor

Separator Vessel

Secondary Operations

- In-house Engineering

- In-house Machine Shop

- In-house ASME Code Weld Shop

- Complete System Integration

- Hazardous or Non Hazardous Electrical Classifications

- Wash Down

- Class 1 Division 1

- Class 1 Division 2

- UL

- CSA

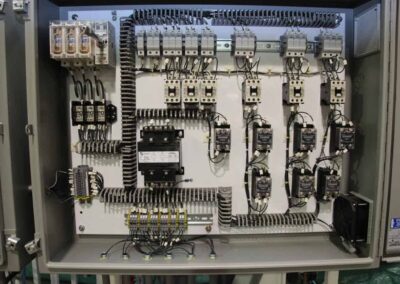

State of the Art Control

Fluitron has the ability to provide any level of control, to meet the customers requirements. Our experience ranges from manual control to fully automated process systems operating in production environments.

- Manual, Microprocessor, PLC, or PC control

- Complete System Integration

- In-house PLC Programming

- In-house Operating Software Program

- Computer Interface

- Data Acquisition

- Pressure/Temperature/Flow/Level Control