If you work in the field of power or clean energy generation, you’ve most probably come across the term SynGas. In this article, you’ll learn what it’s all about and how important it is, especially in the production of clean H2 hydrogen and CH4 methane gas.

What is SynGas

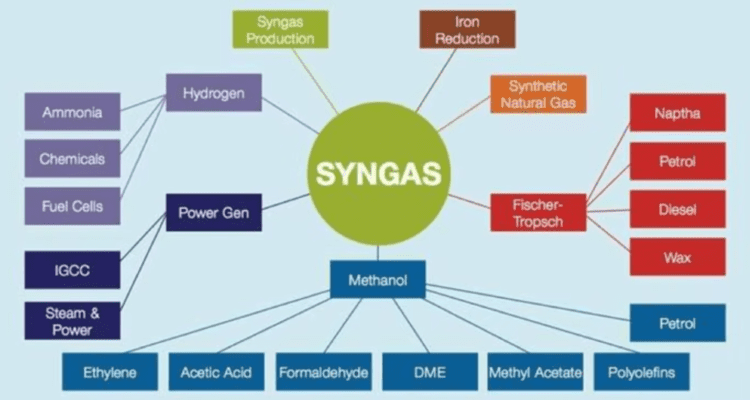

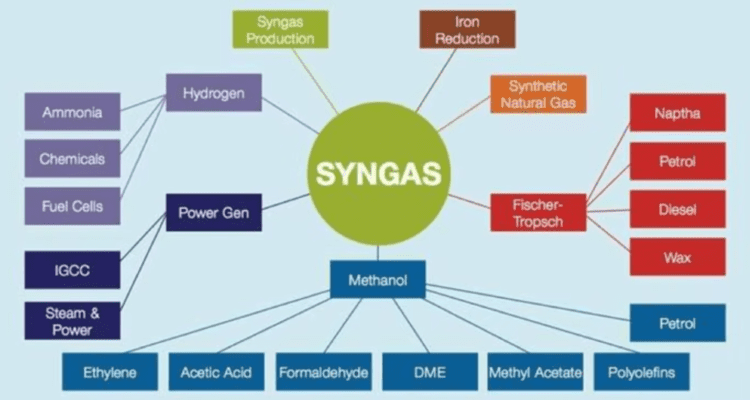

Having 50% of the energy density of natural gases, synthesis gas is a mixture of hydrogen, carbon dioxide, carbon monoxide, and methane gas predominantly. It can be used as a fuel source or as a material that produces other chemicals.

Biomass Gasification Produces Syngas

It is produced through four different phases. The first one is gasification, which converts fuel-containing carbon (e.g., coal, biomass) into a gaseous state. This happens at high-temperatures, while in a high-pressure, and oxygen-depleted environment.

Waste to Energy from Advanced Gasification

Syngas Purification

Then a chemical reaction happens as oxygen-rich materials decompose. In the purification phase, impurities present in the raw SynGas are eliminated. The last phase is the catalytic phase, where eco-friendly fuels can be created through the interaction of SynGas with different catalysts.

Uses of Synthesis Gas

SynGas in Power Generation

From 2020 until 2027, the global demand for this material is expected to have a compound annual growth rate of 6.1%. One of the most common applications of synthesis gas is power and heat generation. This takes place in large-scale power plants or in combined heat and power (CHP) plants. When subjected to heat through pyrolysis (or the process of thermal decomposition at high temperature), the steam generated can be used to power turbine drivers and generate electricity.

SynGas in Fuel Cell Technology

SynGas is also important in fuel cell technology. The extracted hydrogen and methane through SynGas compressors are increasingly used as fuel for the energy and chemical industries. The amount of extracted hydrogen, methane, and other gases depends on the source material. For instance, tires are composed of about 40% methane and 19% hydrogen, while plastics have 38% methane and 25% hydrogen.

Many companies that burn this material use high quality SynGen compressors to recover the hydrogen and methane gas and sell it to fuel cell manufacturers. Fuel cell technology, which enables a device to generate electricity through a chemical reaction, can be applied in power generation for homes, commercial buildings and in electric vehicles.

Hydrogen fuel cells offer an economical alternative for consumers while lowering their carbon footprint. They can also be used to heat water, in the HVAC space, and to cook food.

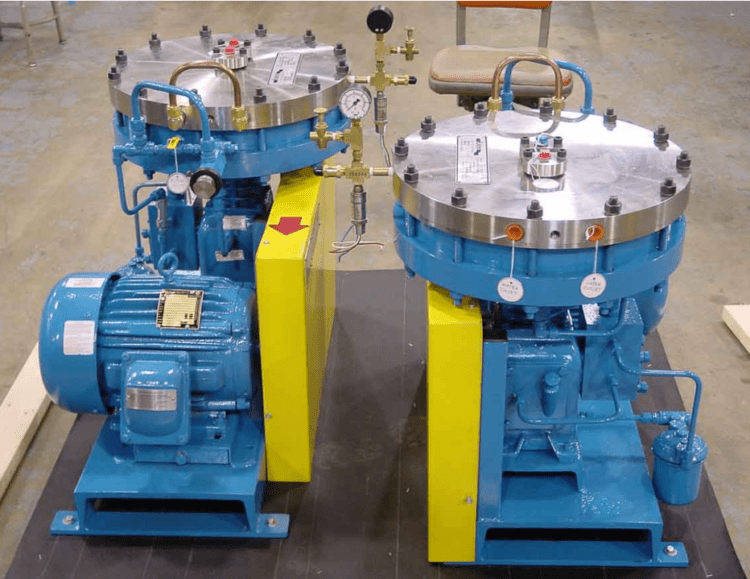

Syngas Compressors Made to Spec

Syngas compression requires a leakproof, oil free, contamination free environment. Our diaphragm compressor designs are a perfect fit for the recovery of synthesis gas during the Pyrolysis and gasification phases of biomass decomposition. Our hermetically sealed compressors are superior to other types because they offer leakage and contamination free compression with reliable operation at operating pressures up to 7,000 and 15,000 psig. Piston and screw type compressors fall short when compared to a diaphragm compressor’s ability to keep your recovered gas clean of contaminants. In most cases, our customers supply us the specifications for custom fabrications based upon there specific applications.

Ready to Have Us Quote on Your Compressors?

Fluitron Incorporated is devoted to providing exceptional products and service. We are always available to discuss client applications and to assist our customers on all of their high pressure needs.

Often, we are asked to rebuild or replace various compressor parts for units manufactured by another company. Fluitron fabricates all of our diaphragm compressors in house and therefore can manufacture custom parts as long as we have the original drawings. It is possible to reverse engineer some components if we are provided the older equipment. Custom made diaphragm compressor parts may or may not be the solution and we won’t know until we examine the failing units. Send us your pictures and details via email to start that conversation.

Syngas to Hydrogen Gas

Scientists and engineers with GE’s Global Research are working with U.S. energy corporations such as Shell-UTC, and Exxon-Mobil to develop the next generation technologies related to gasification, IGCC, syngas, and fuel conversion. Most of this goes beyond the scope of this post and what Fluitron offers the industrial communities it serves. Dr. Ke Liu is the project leader and lead scientist of the team involved. He authored this book, “Hydrogen and Syngas Production and Purification Technologies” that you can buy from Wiley Publishing here.

What we know is that the demand for Syngas compressors and hydrogen compressor systems for energy production & fuel cell technologies is at an all time high. Fluitron will do its part to manufacture best in class compressors that will power our world.